Mercedes-Benz factory tour in Bremen, Germany

Ever wonder why cars cost so much? I took a tour of a Mercedes-Benz factory in Bremen, Germany, recently and gained a much better appreciation of what goes into building a car.

Disclosure: This tour was part of a press trip provided by Bremen Tourismus, Bremen’s tourism board. They have no influence over what I write about the tour.

And another disclosure: This article contains affiliate links. Making a purchase through an affiliate link will mean a small commission for this website. This will not affect your price. Privacy policy.

The factory

The Mercedes-Benz plant in Bremen isn’t their only factory, and it is enormous. The factory’s many buildings cover a campus of about 1.5 square kilometers, almost a square mile. Employing about 11,000 people, it produces about 325,000 cars a year, which is about 1,250 cars every workday. They make 10 different models here, including electric cars and hybrids.

The tour

Given how big the factory is, we only saw a very small part of it. We toured an enormous building where robots organize and attach the metal parts (manufactured in another building we didn’t tour) to make the chassis, and an assembly line where people install the various pieces in and on the car. There was a lot we didn’t see: where the body of the car gets painted in many layers; where any of the other parts get assembled, like the seats or the engines; or the final assembly, testing and cleaning. We did get a brief glimpse of a car on the test track passing over different surfaces and doing a controlled skid.

Tour introduction in the Mercedes-Benz Customer Center

The tour starts in the Mercedes-Benz Customer Center, which looks like a car showroom: very neat and shiny, with high curved ceilings. A couple of vintage cars are on display, as well as some new, sleek models. There’s a shop selling Mercedes-branded merchandise, and a café too. Beyond the café, partly visible in the back, is a big room with a swoosh of neon lights on the wall.

After we placed our coats, bags, phones and cameras in lockers – taking pictures is strictly forbidden inside the factory – our tour guide explained that, despite its appearance, cars are not sold here. Customers buy the cars at dealerships, but the buyers can, if they wish, pick up their cars here. If they do, it becomes a bit of a celebration: they take the same tour of the factory that we took, plus they can pose with their car in front of the shiny neon in the big room in back. They can also try out their new car on the test tracks on the site.

Our first stop was a small theater with a big screen, where we watched what was essentially a slick five-minute Mercedes ad. But the overview of the factory that followed was interesting. Using a view of the factory from above, the guide explained the different parts of the factory and gave an overview of how the raw materials go through all the steps on the way to building a car. The whole process from start to finish takes about a week.

The guide told us about the logistics of this massive undertaking. Finished cars are sent out quickly, so they don’t need a lot of parking spaces. The cars sit in a small parking lot if their buyers will pick them up on the site. For distribution within Europe, a succession of trucks arrive regularly to take the cars to dealers within Europe. The rest are loaded onto trains to go to Bremerhaven, the large port nearby. There, they are transferred onto ships to countries around the world.

On the bus

The guide handed us each a pair of safety glasses before ushering us onto a bus waiting outside. On the way into the factory campus, he pointed out the vocational school which provides many of the plant’s workers. We passed by a train – covered with graffiti – with wagons that are open-ended. Workers drive the finished cars into the train from the back end and through the wagons until the train is full.

We saw quite a few trucks on the roads within the factory campus, and we learned that the plant has no warehouse. Instead, deliveries of parts are timed to arrive as they are needed, and the trucks can drive right into buildings to unload their cargo. Even before seeing inside any of the factory, the efficiency of it all impressed me.

The robot assembly line

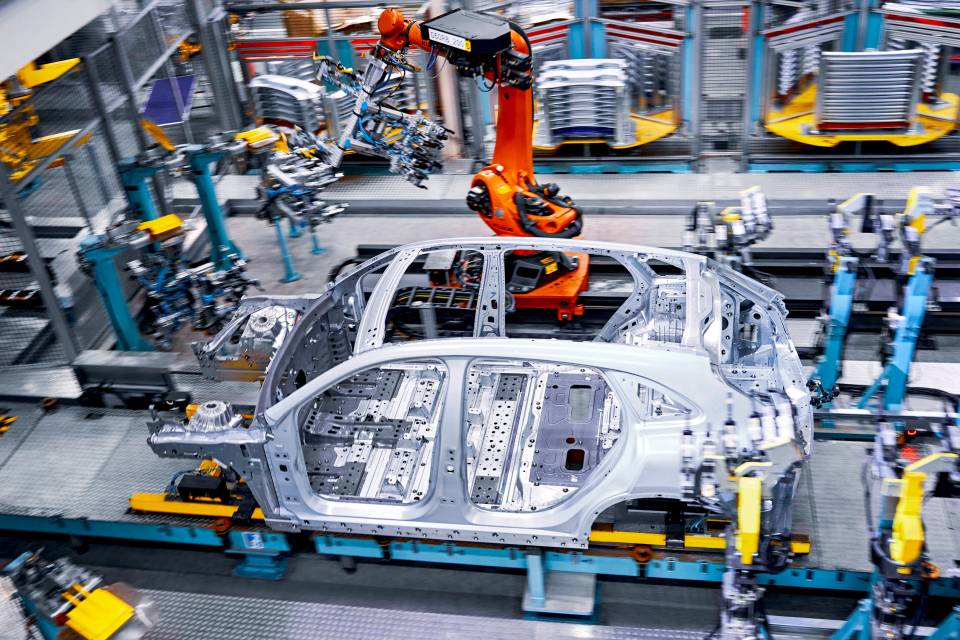

Our first stop took us to see robots busy assembling parts. It was a vast space forming a single assembly line, yet without any identifiable conveyor belt. It didn’t even have any route that I could identify: just spaces defined by fences, presumably to keep humans away from the robots. Between the blocks of fenced spaces, wide “roads” allow people, forklifts and bicycles to get around. This is where we walked.

The massive robots – each with a single, huge orange arm – wielded a variety of different attachments on their arm’s end. Some simply moved things around. For example, arms with big claws collected parts for a single car, lifting them from where they sat on wagons and placing them onto another wagon, which then moved those parts to another spot on the line.

Some robots worked as welders, with heated appendages that would pinch two metal parts so they’d attach together. They even check themselves for deformations of those appendages, replacing them as needed. Or they dispensed glue in precise lines along a section of a chassis, after which another robot pressed a part onto the glue. Other robots simply picked up the welded pieces using pincher appendages that looked like Meccano pieces, and lifted them over fences to where they needed to be next.

It was all just fascinating – even mesmerizing – watching these huge arms / robots do such precision movements, retreating to a resting position between tasks.

The guide explained, as we walked between the robot stations, that this enormous room is one single assembly line for many types and models. Computers control all of it. Parts get barcoded as they go along to determine all of the variables: not only which model the car will be and which body type (convertible, sports, sedan, wagon), but things like which kind of engine (gas, diesel, electric, hybrid, plug-in hybrid), what color has been ordered, which seats, and which extras.

If you’re planning to be in Bremen, read these articles too:

- A weekend in Bremen, Germany: lots of things to see and do, more than you could see in one weekend!

- The Town Musicians of Bremen: a Grimm fairy tale you’ll see in images all over Bremen.

- St. Petri Dom in Bremen: a medieval cathedral, highly decorated inside, with a tower that offers a great view of the city.

The people-operated assembly line

Next we re-boarded the bus to a different building: the place where the cars get assembled. Here we walked up high above the factory work floor, which afforded us a great view of what was happening below.

In this part of the factory, the cars’ bodies have already been painted. Here workers remove the doors again – they were on the car so the paint would match – so that the insides of the cars are easy to reach to install, for example, the electrical systems, engines, batteries, computers, seats, and so on.

It’s all wonderfully cleverly coordinated. We could see the different car bodies move slowly by – convertibles, sedans, wagons, etc. As they move, people, working in small teams of two or three, do just a few small pieces of the job as each car goes by. Supplies, tools and parts arrive in carts on a track that runs parallel to the where the cars move along.

It’s a clean, tidy workplace, and not at all smelly. The line moves constantly but very slowly, snaking back and forth through the massive building.

The workmen seem very relaxed as they work. They’d, for example, take a bumper from a small cart that is conveniently nearby: exactly the right one for the next car arriving at their station. Both workers and robots scan bar codes or QR codes all along the way anyway, just to be sure. They attach a bumper on the front, then another on the back. There’s clearly no rush. Robots move any parts that weigh more than five kilograms, so the workmen also don’t have to do any heavy lifting.

Even the screwdrivers (worth thousands, the guide told us) communicate with the person doing the work. They signal when the right bolts go in the right spots and when they’ve been placed correctly.

We stood above the line as workers placed the electrical wiring. First they dumped a box – arriving on a small robot arm because it’s heavy – of parts into the car, which is mostly just the chassis and the sides at this point. Then they start arranging the wires near where they’ll install them. Workers down the line attach them, either climbing onto the chassis or stepping into the space in front where the engine will be. Further down the line, robots move the engine into place, and we see a robot add a battery into an electric car for the workers to hook up a bit later. A robot with a big claw on its arm places a sunroof on a car.

Again, it’s a mesmerizing thing to watch: almost dance-like. The cleverness of it all is wonderful to see. There’s no wasted movement or materials, all of it happening like clockwork.

To avoid errors, people get rotated to different spots on the line every half hour, so they don’t get too bored. All of these workmen are trained to take any of the spots in this assembly line.

Checking the work

Given the well-planned line and the constant checking, each car comes out as planned: the model, the engine type, the color outside and inside, any accessories that the buyer has ordered. It’s all correct. Nevertheless, the end product gets tested. The finished car is checked that it’s waterproof by, of course, pouring water on it. Then workers polish and check them. About 15% of the cars are tested around the test track, also within the factory campus boundaries.

That was the end of the tour, and we piled into the bus again to go back to the Customer Center. Clearly there’s far more to the plant. Painting the cars takes a whole building of its own, for example, and involves multiple protective layers before adding the actual color. The metal parts that we saw the robots assembling come in from a different assembly line within the factory. They assemble the engines and other elements somewhere else too. The finishing touches – checking everything, placing the tires, re-installing the doors, and so on, happen somewhere else.

Book your accommodations in Bremen here. I stayed at the Radisson Blu Hotel as part of this press trip. Its location is perfect, and my room was spacious and comfortable. It was also very quiet because its window opened on the hotel’s huge, glass-roofed atrium instead of the street.

Should you take this tour?

I considered not taking the tour – cars don’t mean much to me except as a means of transportation. I’m glad that I did, because it was far more interesting than I expected. It would be fun to take a tour in another factory at some point. I’m curious how different it would be in a factory producing a less high-end brand. Do they also produce multiple models on a single assembly line? How do they accommodate the extras that customers order? How much do they make use of robots? Do less fancy cars take less time to produce?

If you’re into cars and you’re visiting the region, you’ll enjoy this tour. Even if cars don’t interest you, you might very well enjoy it as I did.

If you own or aspire to own a Mercedes-Benz, then you’d certainly like it. On the company’s website you can do a deep dive into everything they produce. Contact the Customer Center to book a test drive of one of their 4x4s, if that’s something you’d enjoy. You might also want to visit Stuttgart to see the Mercedes-Benz Museum.

The tour seems wheelchair accessible using elevators instead of stairs. I’m not sure, however, how wheelchair accessible the bus is. Ask before you sign up.

While the tour is open to children from 6 years old, on the factory floor where the robots are, I noticed lots of computers and other machines outside the robots’ fenced-in workplaces, right next to the “roads” we walked on. Those machines had lots of brightly-lit buttons within reach of small children. It seemed to me that they might be hard to resist for the littler kids. The guide suggested no younger than 9 years old, but of course it depends on the child.

Mercedes-Benz factory: Im Holter Feld, Bremen. The tour takes about two hours and can be in either English or German. The tours in English are on Fridays at 14:30. They cost €22 for adults and €19 for children 6-17 years. Book the tour with Bremen Tourismus.

Is this something you’d enjoy doing? Have you toured any other car factories? Add a comment below!

My travel recommendations

Planning travel

- Skyscanner is where I always start my flight searches.

- Booking.com is the company I use most for finding accommodations. If you prefer, Expedia offers more or less the same.

- Discover Cars offers an easy way to compare prices from all of the major car-rental companies in one place.

- Use Viator or GetYourGuide to find walking tours, day tours, airport pickups, city cards, tickets and whatever else you need at your destination.

- Bookmundi is great when you’re looking for a longer tour of a few days to a few weeks, private or with a group, pretty much anywhere in the world. Lots of different tour companies list their tours here, so you can comparison shop.

- GetTransfer is the place to book your airport-to-hotel transfers (and vice-versa). It’s so reassuring to have this all set up and paid for ahead of time, rather than having to make decisions after a long, tiring flight!

- Buy a GoCity Pass when you’re planning to do a lot of sightseeing on a city trip. It can save you a lot on admissions to museums and other attractions in big cities like New York and Amsterdam.

- Ferryhopper is a convenient way to book ferries ahead of time. They cover ferry bookings in 33 different countries at last count.

Other travel-related items

- It’s really awkward to have to rely on WIFI when you travel overseas. I’ve tried several e-sim cards, and GigSky’s e-sim was the one that was easiest to activate and use. You buy it through their app and activate it when you need it. Use the code RACHEL10 to get a 10% discount!

- Another option I just recently tried for the first time is a portable wifi modem by WifiCandy. It supports up to 8 devices and you just carry it along in your pocket or bag! If you’re traveling with a family or group, it might end up cheaper to use than an e-sim. Use the code RACHELSRUMINATIONS for a 10% discount.

- I’m a fan of SCOTTeVEST’s jackets and vests because when I wear one, I don’t have to carry a handbag. I feel like all my stuff is safer when I travel because it’s in inside pockets close to my body.

- I use ExpressVPN on my phone and laptop when I travel. It keeps me safe from hackers when I use public or hotel wifi.